Basic Characteristics

Anticipating a ventilator shortage in Europe during COVID-19, my team adapted a 2018 veterinary ventilator for human use. Despite resource and supply challenges, we registered it with Anvisa for non-life-support use within five months, with plans to produce up to 3,000 units monthly at the crisis's peak.

Although large-scale production was not realized due to timing, we continued improving the ventilator, integrating features like cloud connectivity to transmit critical ventilator and patient data. As a bonus, I gained valuable experience in how large-scale companies organize their development, production, and quality systems.

System Characteristics

- Compliant with IEC 60601-1, 60601-1-2, 60601-1-6, 60601-1-9, and 60601-1-11.

- Hard real-time system controlling a 50W BLDC motor.

- Hard real-time system with 50W BLDC motor control and pressure/flow conversion.

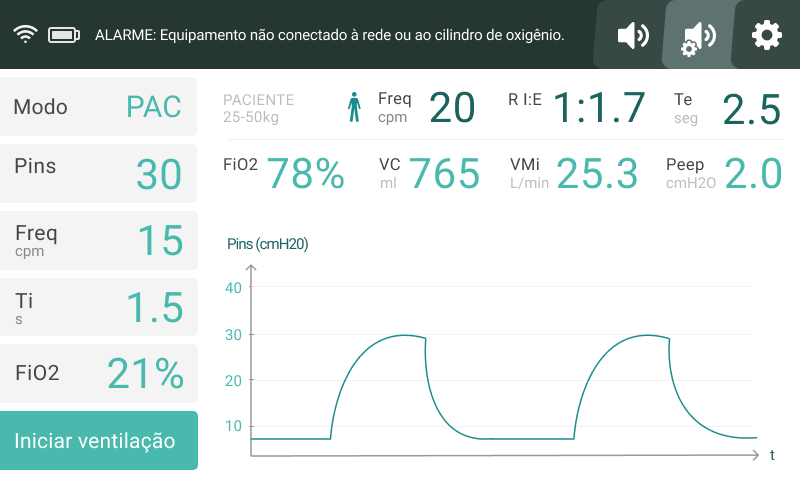

- 7" touchscreen interface with system redundancy.

- Designed to handle critical part shortages.

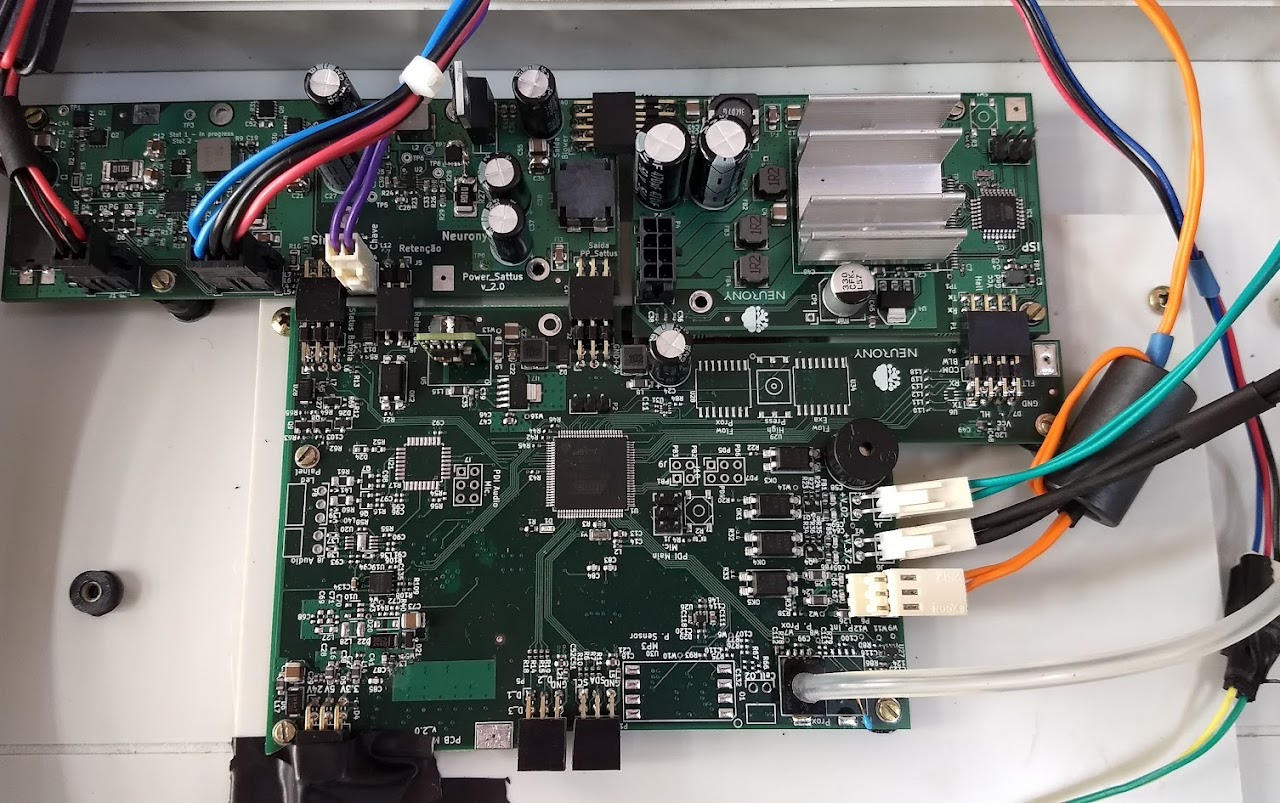

- Built with three four-layer PCBs.

- Features a 4-cell, 100W LiPo battery charger and 100W boost converter.

Areas that I had specifically worked on or led

- Product Owner, leading embedded code development in C.

- Designed all three PCBs: main controller, BLDC controller, and power conditioner.

- Represented the company during certification testing and production of the trial batch.

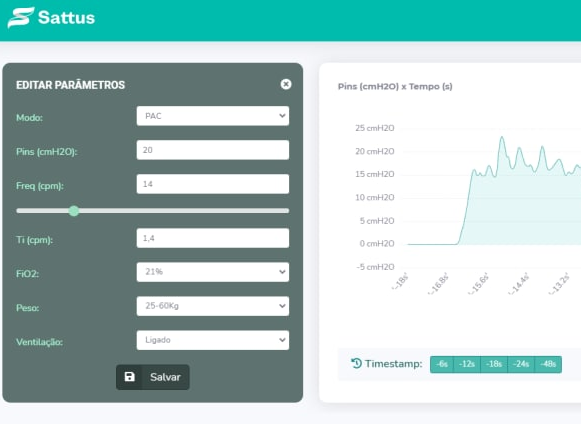

- Contributed to software documentation, risk analysis, and IoT cloud integration.

- Developed production and testing equipment designs.

Gallery

One of the production test jigs

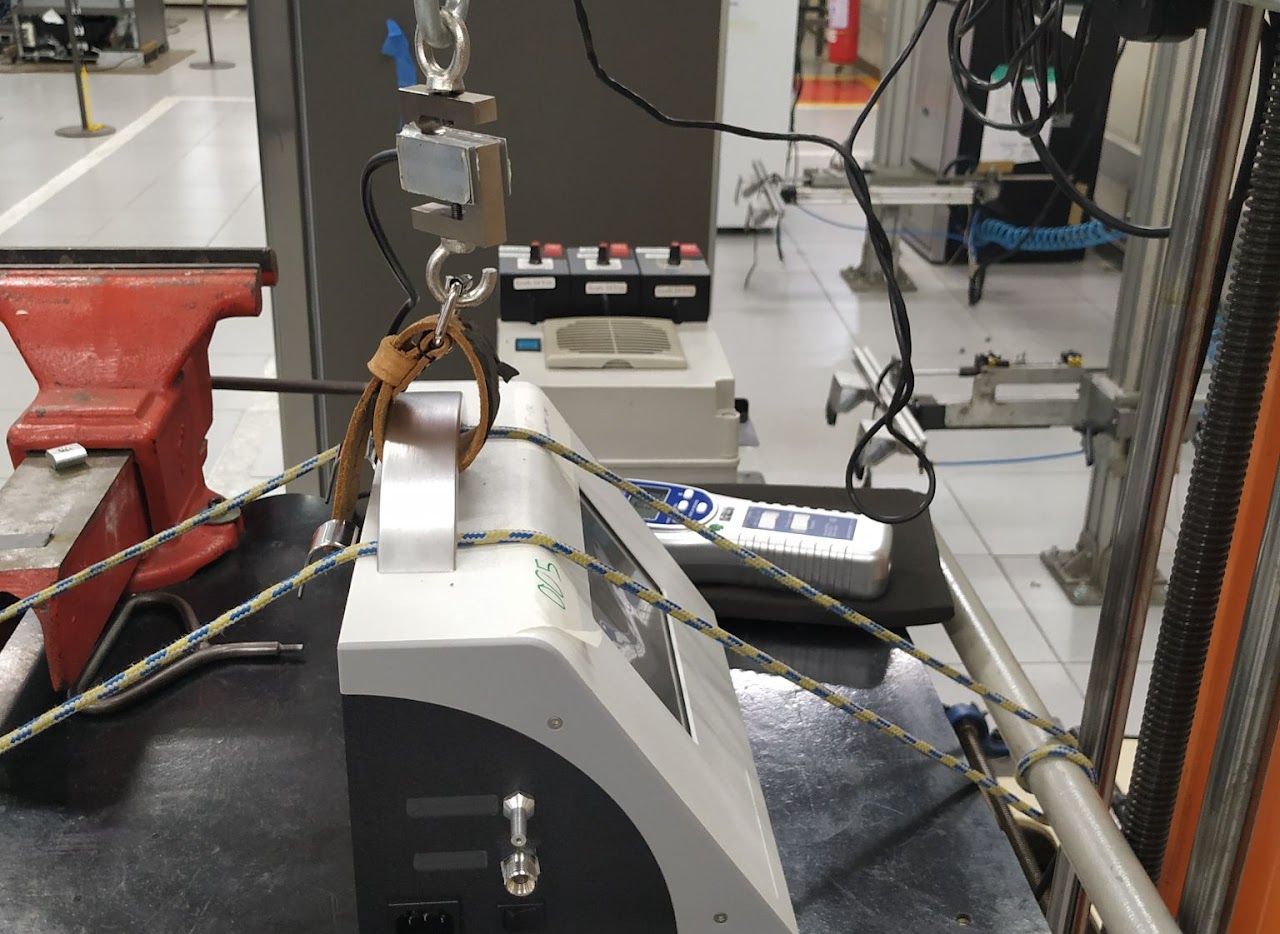

IEC 60601-1 vibration tests

IEC 60601-1-2 radiated emissions test